Coronavirus Thrusts Supply Chain into Crisis Spotlight

Apple rarely lowers its quarterly guidance – it did so in February, citing the impact of the Coronavirus on its supply chain as one of the major reasons.

Rio Tinto on February 26th announced a 41% decline in annual net profits while warning about the impact of the virus on its supply chain.

Microsoft on the same day, and for the same reason, revised downwards its revenue guidance.

Thousands of smaller sellers on Amazon, who built their businesses using China’s cheap manufacturers, are running low on product and raising prices to stop people buying their products – an odd impact of how Amazon’s all-powerful algorithm demotes sellers who run out of stock.

Supply chain risk is one of those old-school issues that companies address every year – hence it rarely makes the news.

Coronavirus has changed that!

In fact, supply chain is having a moment.

For a very different reason than Coronavirus, coffee company Nespresso hit the headlines in late February with problems in its supply chain.

In this case the issue was the alleged use of child labor on the Guatemalan farms where the company sources its coffee beans.

A British TV company filmed the children on the farms – and then the issue really blew up when Nespresso brand ambassador George Clooney issued a statement saying he was ‘saddened’ by what he had seen in the TV footage.

A recent Deloitte survey found that 85% of supply chains have experienced at least one disruption in the past 12 months.

It is not possible to anticipate every risk, therefore a so-called ‘Black Swan’ event like the worldwide outbreak of Coronavirus may not have been a risk for which you had a plan.

However, there are many events and disruptions that can be anticipated – and must be covered in your strategy to manage supply chain risk.

Now would be a good time to ensure that you have up-to-date systems and processes to manage risk in your supply chain.

Many of the more recent best practice developments focus on technology applications to help identify and manage threats to supply chains.

Here’s some of the new ways that technology is aiding and abetting risk management:

- Data Analysis: In this digital age, you are gathering a lot of information about the performance of your supply chain. Over time, the analysis of this data offers insights into the most effective suppliers, modes, carriers, routes and partners.

There’s an interesting overview of the whole topic of the uses of data in supply chain analytics here.

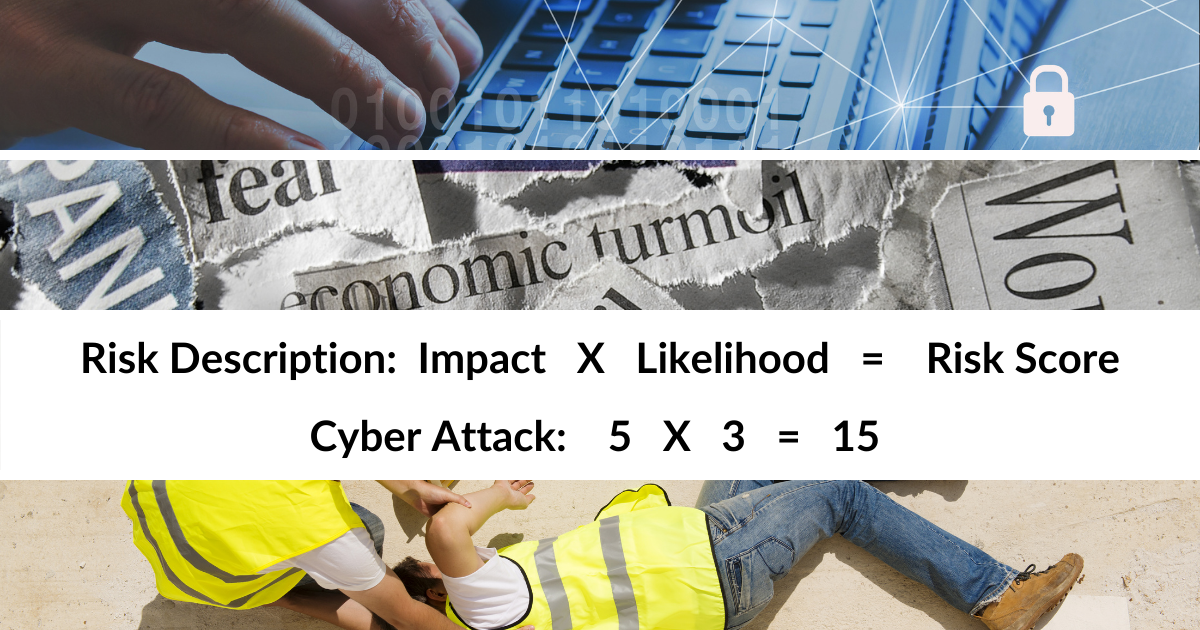

- Risk Management Dashboard: Managing risk is not only a task for the supply chain risk management team – when it works well, it also involves functions such as marketing, IT and legal.

To work effectively, this extended team needs an interface, a risk management dashboard, where information about trends and disruptions can be shared in real time, with push notifications at the earliest stage when adverse events are detected.

- Tracking location: For physical products, sensors placed on pallets or packages to transmit data will provide information on everything from environmental conditions, through to compliance issues and unnecessary delays in transportation.

- Crisis management: A key element of any risk plan is preparation for that moment when things do go wrong and do so publicly (Nespresso and Mr Clooney being good examples).

The response management is likely to involve teams in different locations and time zones and will need to be quick and effective.

To instantly access crisis protocols and activate the team, organizations are increasingly adopting mobile issues management platforms, like our own In Case of Crisis.

Learn how hundreds of organizations large and small are using our award-winning crisis management platform, In Case of Crisis, so you can be better prepared and respond faster to emerging threats like Coronavirus.